The best coil winding machines for ultra-fine wire and optical fibers

Realize your machine and production with the best winders, spoolers and components of winding technology.

For ultra-fine wire, flat wire, tape, foil, filament, optical or thermoplastic fibers.

One modular system, diverse solutions.

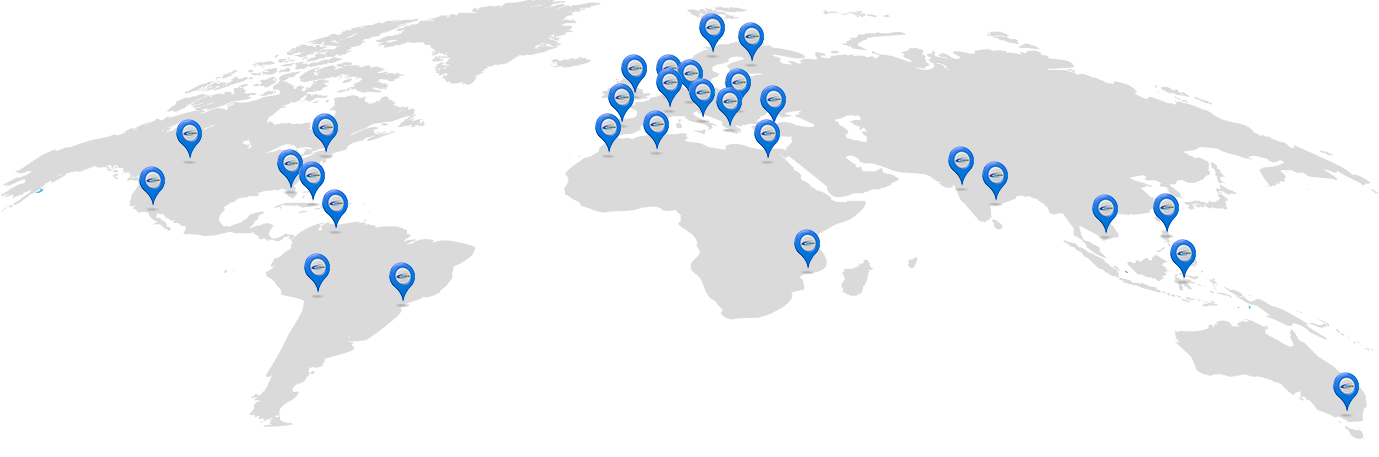

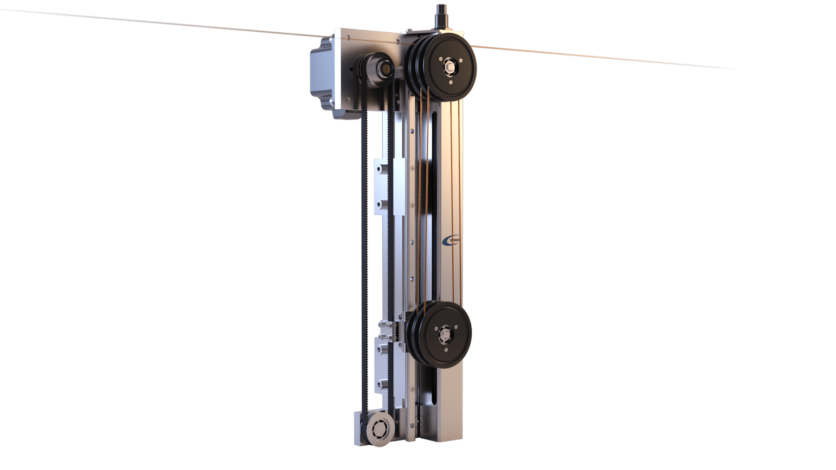

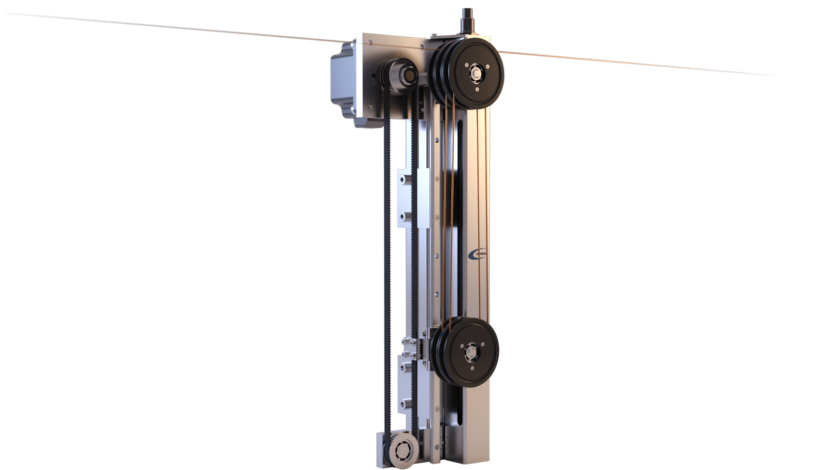

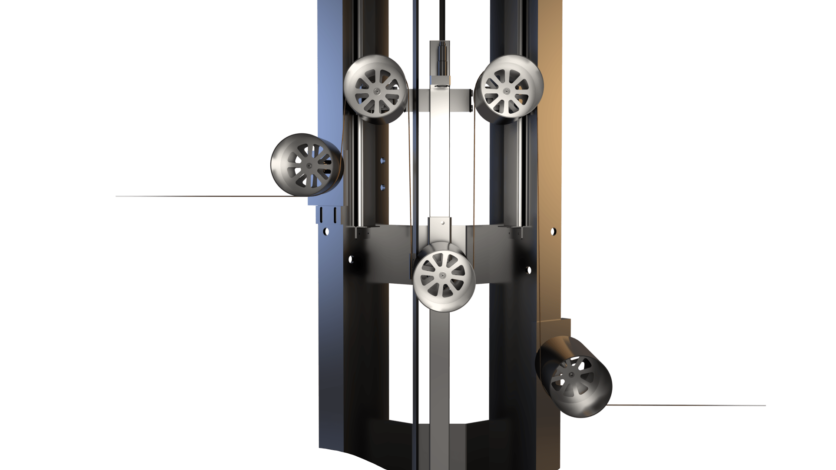

Winder and Spooler with innovative motor and traverse unit

Spooling machines with ED-, MW- and SW-class winders as pay-off and take-up units, are perfect for high precision winding and spooling. The electronic traverse unit systems from Supertek are important to realize precise spooling patterns. The ED- and MW- class winders have a high-resolution motor with a shaft for the bobbins. The SW-class winders are shaftless and can automatically clamp the bobbin. Automatic spool, bobbin or coil change is also possible. For straight-line winding, e.g. of flat wire, optical fiber, the MW- and SW- class winders have a linear drive that moves the entire spooler linearly.

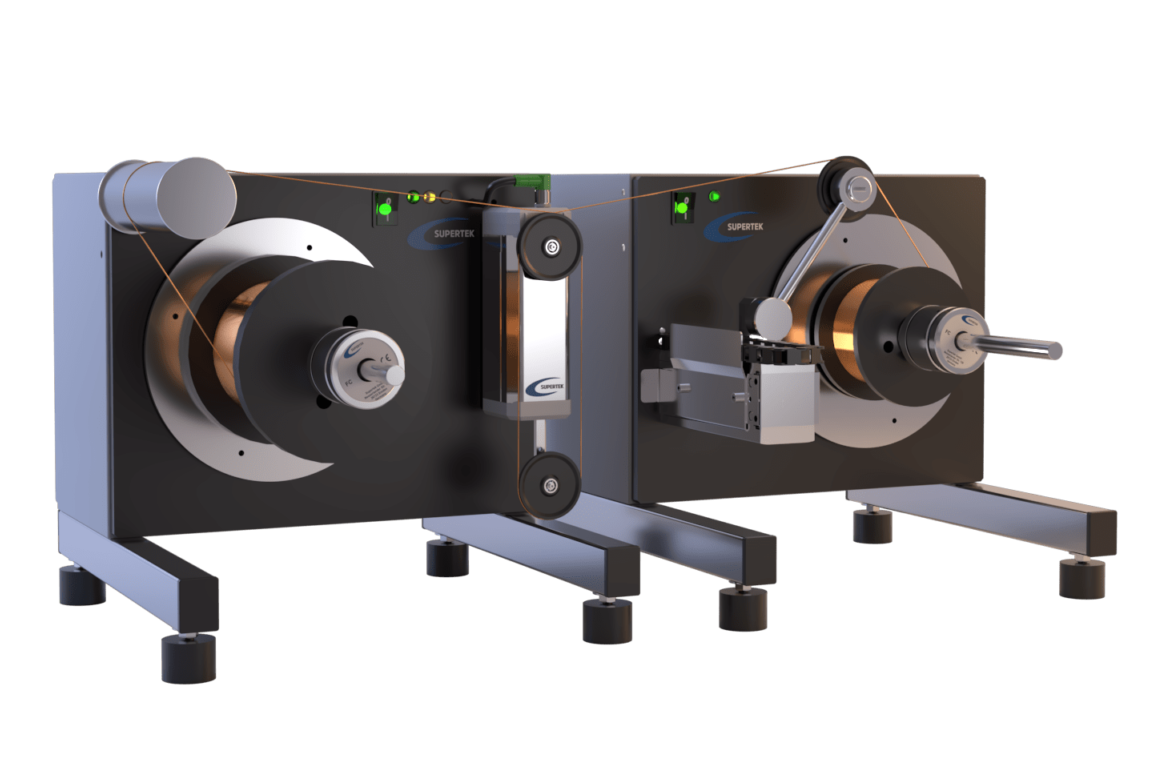

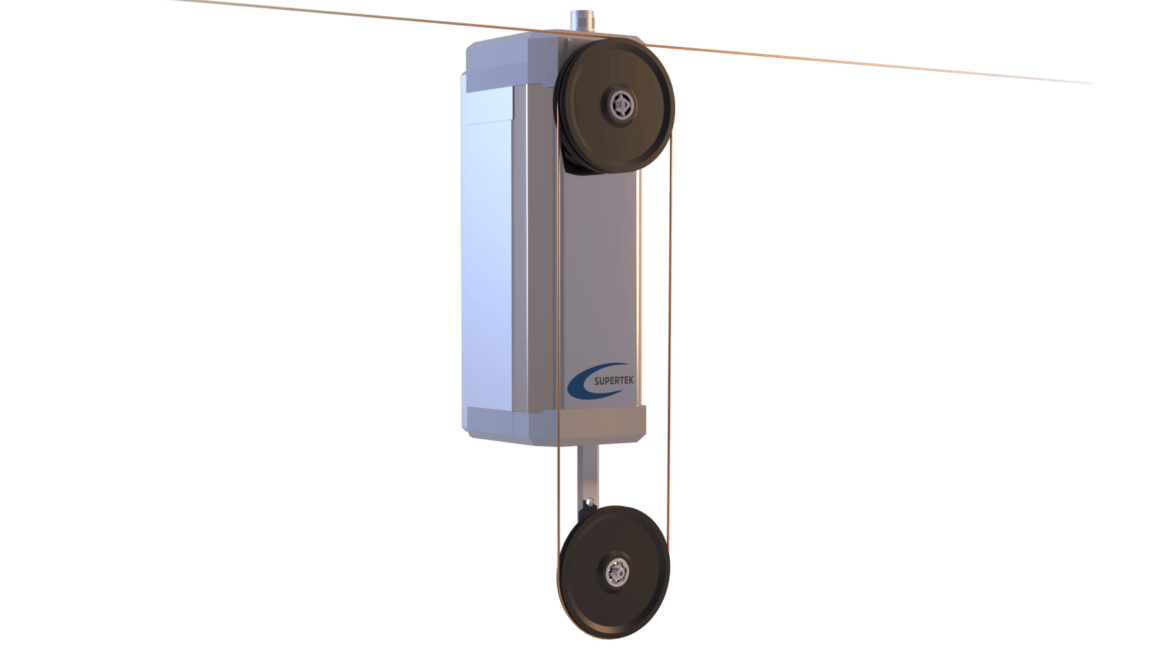

ED class winder

Winder and spooler for small spools, thin wires and fine fibers for unwinding, respooling, winding and rewinding. Pay-off and take-up unit available as tabletop system.

- Electronic traverse unit

- Shaft winder

- Coil weight up to 5 kg

- Coil diameter up to 260 mm

- Laying width up to 250 mm

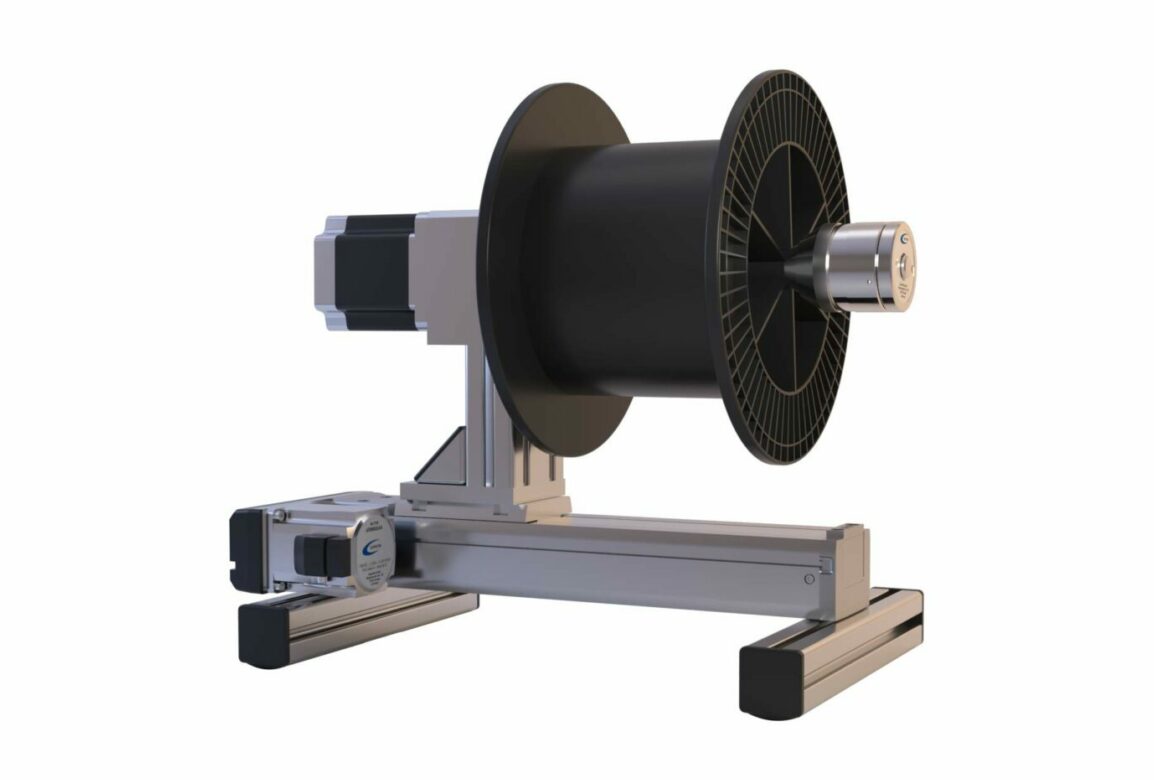

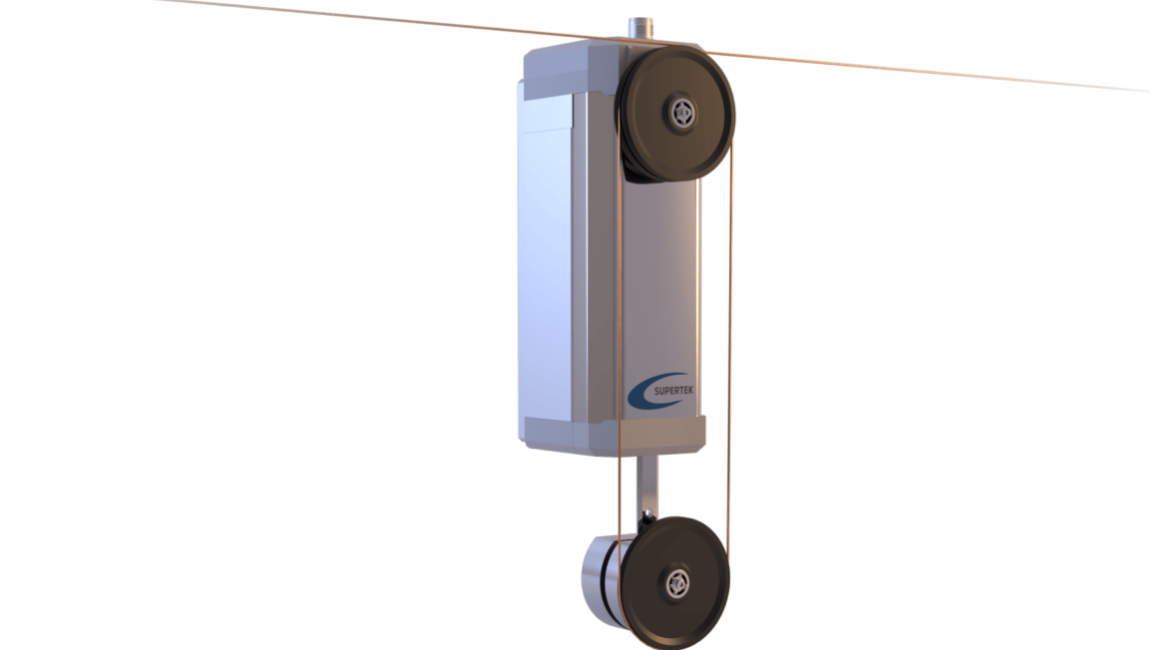

SW class winder

The professional solution for unwinding, winding and rewinding spools for round and flat wires, foils and optical fibers. Automatically traversing coil for laying precise winding.

- Electronic traverse unit for a automatic moving spool

- Spool traverse shaft winder

- Coil weight up to 10 kg

- Coil diameter up to 360 mm

- Traversing width up to 250 mm

SW class winder

The high-precision solution for the automated unwinding, winding and rewinding of a wide variety of coil shapes, round and flat wires, foils, tapes and fibers. Automatically traversing bobbin with opposing clamping unit.

- Automatic traversing coil

- Automatic clamping unit

- Automatic spool change optional

- Spool weight up to 25 kg

- Traverse unit up to 325 mm

- Coil diameter up to 460 mm

Dancer Tension Control for fine wire and optical fiber

Patented Electromagnetic Dancers for constant tension and high-precision tension control.

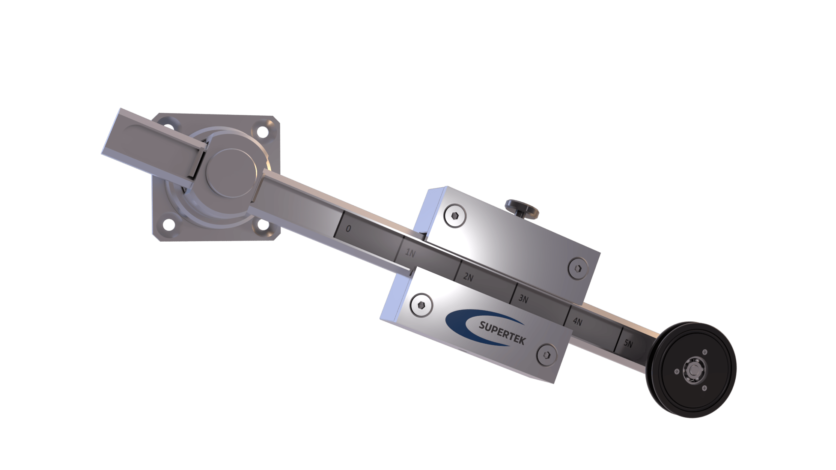

Electromagnetic dancer EDR 10

The electromagnetic dancer EDR 10 for high precision tensile forces 2 mN to 1000 mN

- Dancer force 4 mN to 2000 mN

- Patented electromagnetic force generation

- Constant force regardless of the dancer position

- Highly dynamic

- Force setting analog or digital in 1 mN steps

- Use for sensitive fibers and fine wires

Electromagnetic dancer EDL 60

The electromagnetic dancer EDL 60 for high-precision tensile forces 10 cN to 600 cN

- Dancer force 20 cN to 12 N

- Patented electromagnetic force generation

- Constant force regardless of the dancer position

- Highly dynamic

- Force setting analog or digital in 1 mN steps

- Use for thin wires and glass fibers

Electromagnetic dancer EDL 60G

The electromagnetic dancer EDL 60G for precise tensile forces 100 cN to 900 cN

- Dancer force 200 cN to 18 N

- Patented electromagnetic force generation plus weight

- Constant force regardless of the dancer position

- Force setting analog or digital in 1 mN steps

- Use for fibers and wires

Winding Tension Control

Dancer Controller and Accumulators with a lot of storage capacity and for high tensile stresses.

Electronic linear dancer EBL 100

The electronic linear dancer EBL 100 with a lot of power and a large dancer stroke up to 10 N

- Dancer force up to 20 N

- Electronic force generation

- Force setting analog or digital

- Use for wires and foils

- Non-contact position detection

Electronic linear dancer EBL 500

The electronic linear dancer EBL 500 with a lot of power and a large dancer stroke up to 50 N

- Dancer force up to 100 N

- Electronic force generation

- Force setting analog or digital

- Use for wires and foils

- Non-contact position detection

Mechanical rotary dancer GDR 100

The mechanical rotary dancer GDR 100 for robust applications.

- Dancer force up to 20 N

- Tensile force with a wrap up to 10 N

- Mechanical force generation

- Force setting manually via weight

- Non-contact position detection

Automation of winding

Winding Controller and software for efficient and precise winding processes.

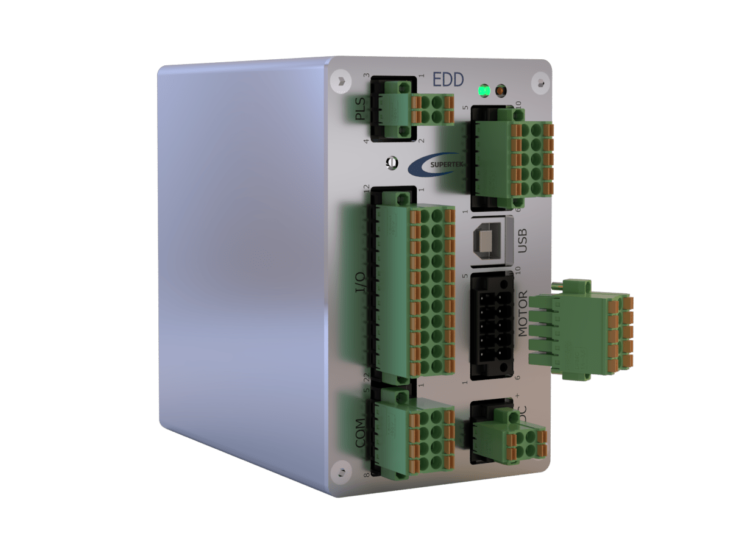

Dancer controller EDD

The EDD dancer controller provides all the necessary functions for tension and dancer position control.

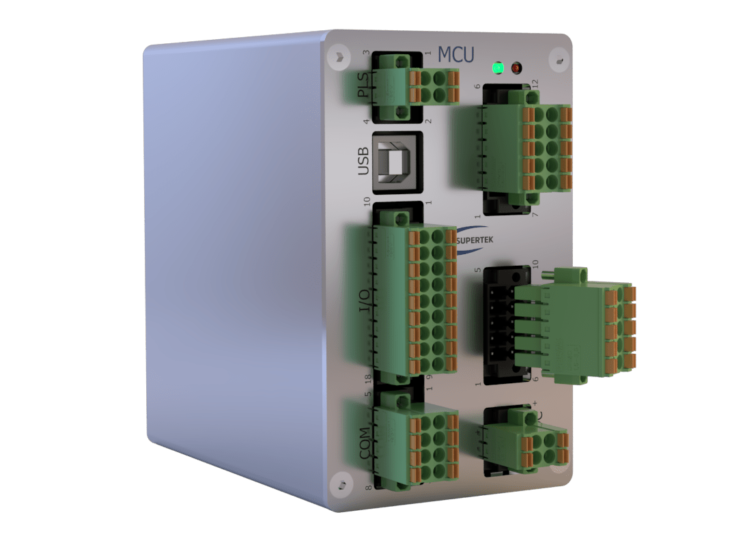

Winding Controller MCU

Easy operation and monitoring

The Winding Controller MCU is a processor-controlled real-time solution for high-precision laying during winding and contains all powerful software functions for unwinding, winding and rewinding.

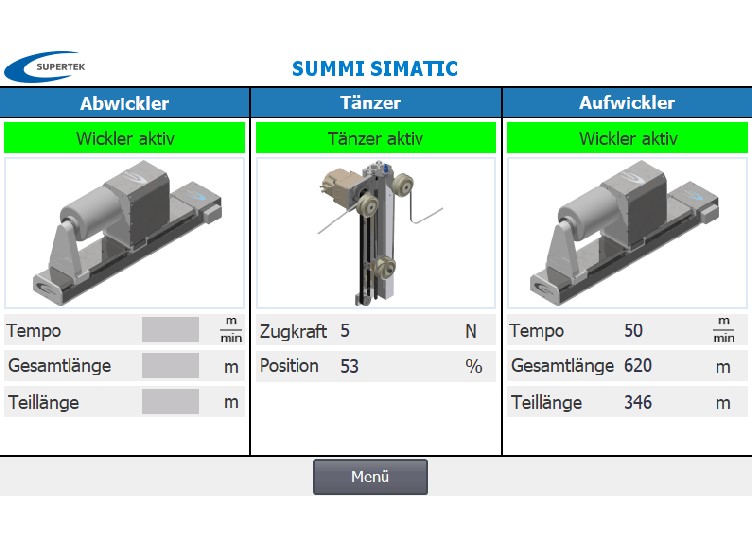

Software SUMMI pro

The SUMMI pro software is an HMI user program for touch panel PCs, notebooks and tablets with Windows for easy parameterization of dancer controllers and winding computers and is suitable for the operation and monitoring of unwinding, winding and rewinding machines.

Operating and Monitoring in the Winding Technology

Operating and monitoring of winding machines with industrial HMI and touch panel.

The control panels are suitable for the easy operation and monitoring of winding machines.

Operating unit CMC

The compact operating and control unit for parameterization and operation of EDD and MCU.

MTP SUMMI-PC control panel

The support arm control panel for unwinding, winding and rewinding machines with PC touch panel for SUMMI-PC software.

Coil Scanner and Position Scanner

Sensors for precise winding patterns and straight-line spooling.

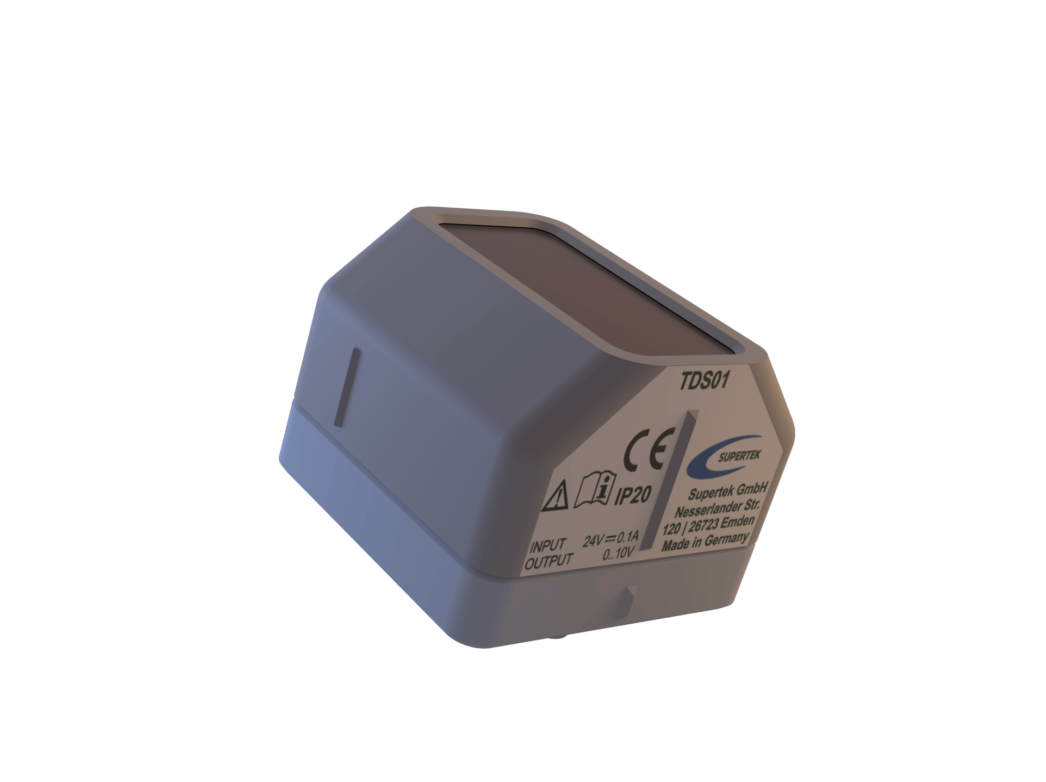

Coil Scanner TDS 3D

The 3D coil scanner measures the coil geometry in real time.

With the spool scanner, the flanges of a spool and the winding pattern are automatically recognized. In combination with the Winding Controller MCU, perfect winding patterns are also created on conical spools.

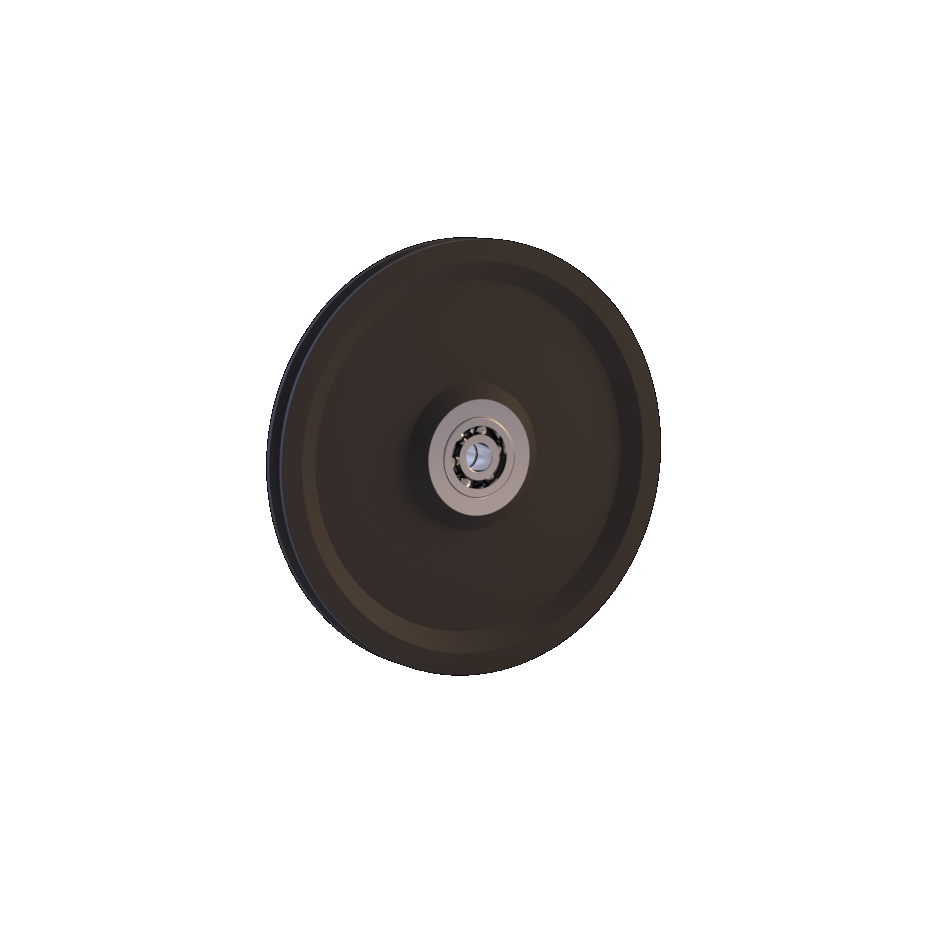

Guide Pulleys

Cable Pulleys, Wire Pulleys and Optical Fiber Pulleys from Supertek are ideal for smooth winding processes.

German quality - Globally trusted. Here's where we're already in action.

Let Us Impress You Too!