Optical Fiber Coloring Rewinder Machine

Fiber optic cable are colored with UV-crosslinked lacquers and dried with UV light. A particularly gentle coloring of the fiber is achieved by a straight fiber flow and a low fiber tension. Both criteria are met even at very high speeds with Supertek's winding technology.

The traversing coil axis of the MW or SW class enables the optical fibers to run in a straight line. The position of the fiber is detected contact-free with the position scanner. This means that automatic, straight-line unwinding is possible on the pay-of side. A homogeneous coil pattern is achieved when winding with the traversing winder and the coil scanner. The spool scanner regulates the reversal points with the automatic flange detection and ensures that the fiber is accurately placed on the coil. High precision tension control is provided with Supertek's patented electromagnetic dancers. The belt type capstan from Supertek are used for a desired decoupling of tension. In this case, the belt type capstan takes over the speed control and the unwinders and winders are each controlled by the dancers. SW class winders are used for high speeds and automatic bobbin changers.

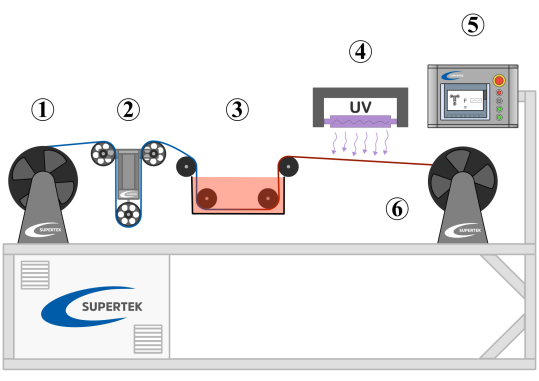

Coloring process of fiber optic cable.

- unwinder, pay-off unit

- tension controller

- coloring bath

- UV drying

- HMI

- rewinder, take-up unit