Wire Annealing

Supertek's spooling equipment and winding technology are used for annealing wires and fine wires with the highest demands on material grade and quality.

Supertek supplies all the components needed to accurately draw thin wires through a wire drawing furnace. The highly sensitive tension is finely and reproducibly controlled by our patented electromagnetic dancer. The traversing coiler and the position scanner ensure a straight alignment of the wire. Over the entire distance between decoiler, annealing furnace and recoiler, the wire is always kept in line and centered to the working tube. Traversing winders can be configured with the MW- class or SW-class. With Supertek's winding technology you get:

- precise tension

- exact speed

- accurate windings

- high material quality and best quality

Let yourself be inspired by our winding technology for your annealing processes!

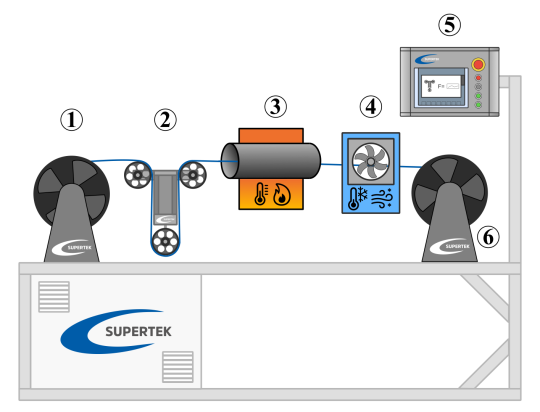

Wire Annealing Process

- Decoiler / Unwinder

- Electromagnetic dancer

- Annealing furnace

- Cooling

- HMI

- Spooler / Rewinder