Optical Fiber Drawing Tower

When drawing an optical fiber or glass fiber, high-precision processes are required in the drawing tower. For use in the draw tower, you can get the subsystems belt type capstan, tension dancer control and bobbin winder from Supertek. The specification for the fiber diameter and the tensile strength of the fiber are particularly relevant when drawing.

Fiber Optic Draw Tower

drawing process

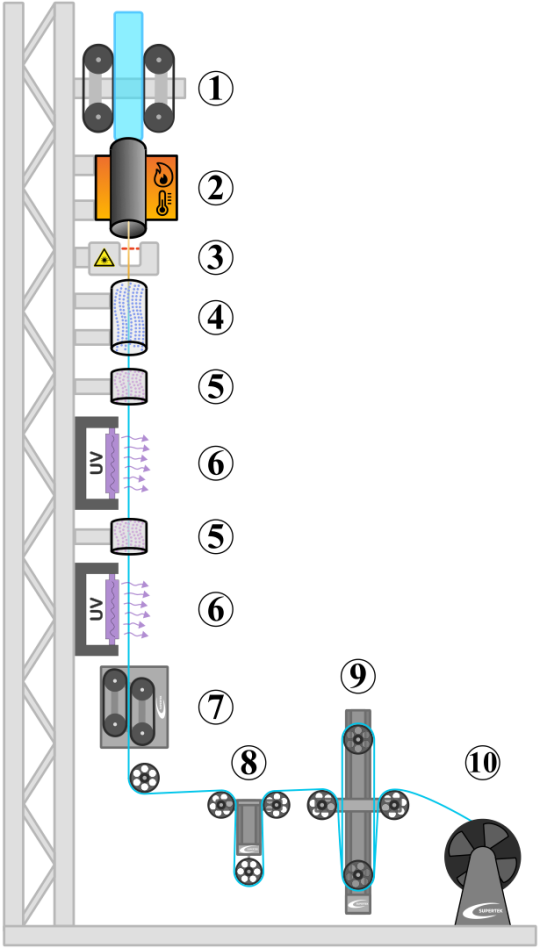

Draw tower and the subsystems of Supertek

After feeding the preform in the preform feed module into the drawing furnace, further processes are necessary in the drawing tower. The capstan or belt haul-off is used as the main haul-off and thus as the fiber draw. For this purpose, Supertek offers special capstans or haul-offs. The Supertek draw-off controls the precise speed of the fiber as it is drawn and decouples the tension or pull force between the draw operation and the take-up spool.

With Supertek's tension controllers, the tension is controlled based on the process and is regulated with high precision. For tension control of glass fibers, the electromagnetic dancers with a resolution starting at 1 mN are particularly suitable. For winding the fiber onto large carrier spools, Supertek's MW- or SW-class winding machines are suitable. For spool changing without process interruption, Supertek offers suitable fiber or dancer accumulators. With our winding machine and tension controller, the fiber is very gently and precision wound onto the winder spool.

- Preform tracking

- Drawing furnace

- Fiber diameter measurement, laser inline measurement

- Fiber cooling tube

- Fiber coating

- UV curing

- Capstan, main haul-off

- Tension control

- Fiber accumulator, dancer accumulator

- Rewinder / Spooler, Winding machine