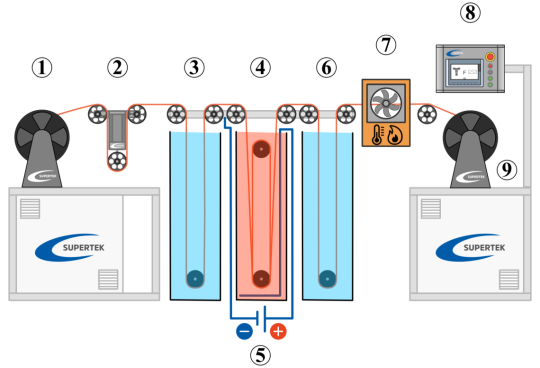

Electroplating of wire

Electroplating is used to coat the surface of wires, usually copper wires, with e.g. tin, nickel, silver or gold. The electroplating equipment requires an electrolytic bath for the electrochemical deposition of metallic coatings on the wire which forms the substrate. In the electrolytic bath, electrolysis (direct current) transfers the coating material from the anode (positive pole) to the cathode (negative pole). For a high coating quality by electroplating, the precise control of the passage speed in the electrolytic bath and the tensile stress from the wire are also important.

For the unwinding and rewinding of fine wires, Supertek provides you with the professional equipment of the electroplating line with unwinders, rewinders, capstans and precise tension control.

- Unwinders, pay-off unit

- Dancer

- Bath (A)

- Electolytic bath (B)

- Direct current for electrolysis

- Bath (C)

- Drying

- HMI

- Winder, take-up unit