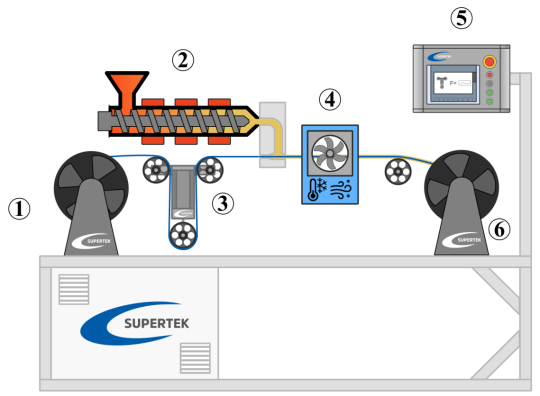

Sheathing Extrusion

There are different methods of sheathing wires or fibers. In the case of extrusion coating, coating is carried out using pressure coating or, for thin layers, using the tubular stretching method. In addition to the extruder and the cooling trough, winding technology components are required for the wire sheathing. Supertek offers the appropriate pay-off and take-up components for precision wire coating machines. The unwinders and winders are available in different versions for the finest wires and a wide variety of coils. We will provide you with the appropriate trigger for controlling the speed and the perfect tension controller for precise tension.

Sheat extrusion process

- Pay-off unit

- Electromagnetic Dancer

- Cooling section

- Control Panel / HMI

- Rewinder