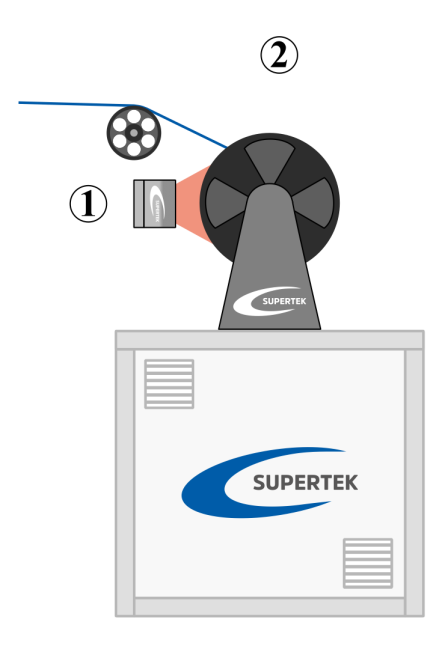

Take-up winder

Take-up Winders are winding machines used in industrial processes to wind materials such as fibers, wires, films, or tapes evenly onto spools or rolls. It is commonly employed in the production of optical fibers, wires, textiles, and films, ensuring that the material is wound precisely and without damage.

Functionality

The take-up winder continuously collects material from the production line and winds it onto a roll or spool. Various mechanisms are used in the process:

- Tension Control – ensures that the material is wound with consistent tension to avoid deformation.

- Speed Control – adjusts the winding speed to match the production speed.

- Layer Control (Traversing) – enables the even distribution of material across the spool.

Applications

- Fiber Optic Production: Winding glass fibers after the drawing process.

- Wire Industry: Winding fine wires or cables.

- Textile Industry: Winding yarns or textile tapes.

- Film Production: Winding plastic films or other thin materials.

Types of Take-up Winders

- Automatic Winders: Automatically replace the spool when it is full.

- Manual Winders: Require manual intervention for spool changes.

- Precision Winders: For high-precision winding of sensitive materials.

Features

- Uniform winding to prevent material overlap

- High precision and tension control

- Flexibility to accommodate different spool sizes and materials

- Automatic or manual operation modes

Technical Advantages

- Reduction of material waste

- Optimal material utilization through precise control

- Efficient production processes at high speeds

Take-up Winders are essential for many industrial processes that rely on precise and controlled winding to maintain material quality and production efficiency.