Bandwickler

The band winder is designed for winding band materials and strands onto defined spool types. The device operates without traversing, meaning the band is applied in a fixed winding position. This results in a uniform winding structure with controlled tension throughout the entire process.

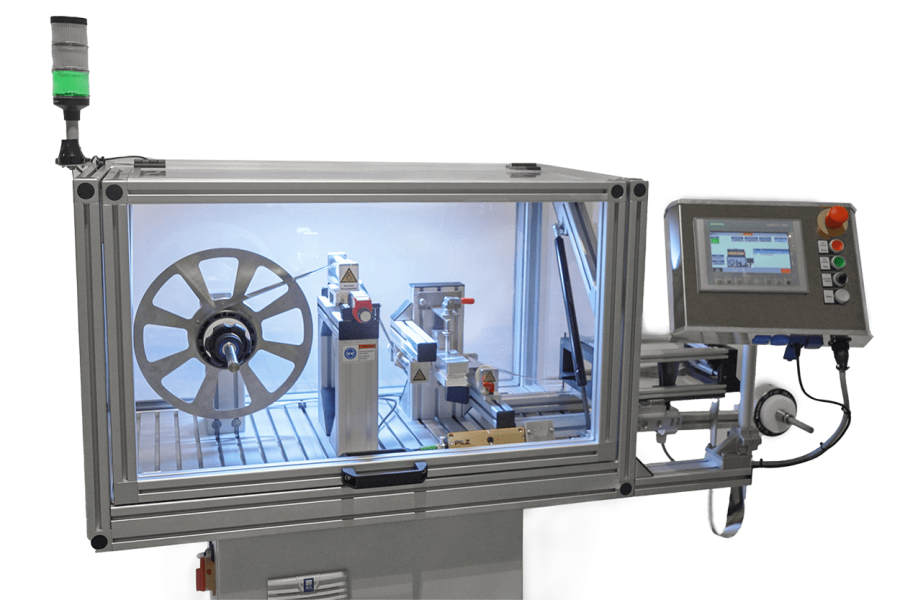

The machine is housed in an enclosed protective frame with a viewing window. The winding process is operated and monitored via a central control unit with a touch panel. All process parameters such as torque, speed, and band tension can be adjusted and monitored through the control interface.

Technical Features:

✅ Low-friction band guidance

✅ High winding speed

✅ Rigid frame with integrated protective enclosure

✅ Touch panel with clear process visualization

✅ Sensor-monitored safety functions (door monitoring, emergency stop, status indicator)

✅ Modular design for variable spool sizes and band widths

The band tension is kept constant by a regulated dancer system or torque control. The drive system is servo-controlled, automatically adjusting to the increasing spool diameter. This ensures stable material tension and a reproducible winding process.

The band path is clearly structured and designed for minimal friction. Deflection rollers made of wear-resistant materials ensure gentle handling, even for sensitive materials. The modular machine concept allows easy adaptation to different spool sizes, band widths and winding lengths.

For process monitoring, the system is equipped with integrated sensors and an optional signal tower. Safety features such as door monitoring and emergency stop are built in. Depending on the application, the band winder can be operated as a standalone unit or integrated into a production line.

Due to its compact design, easy accessibility and precise control, the band winder is suitable for laboratory, testing or production environments where defined and repeatable winding without axial movement is required.